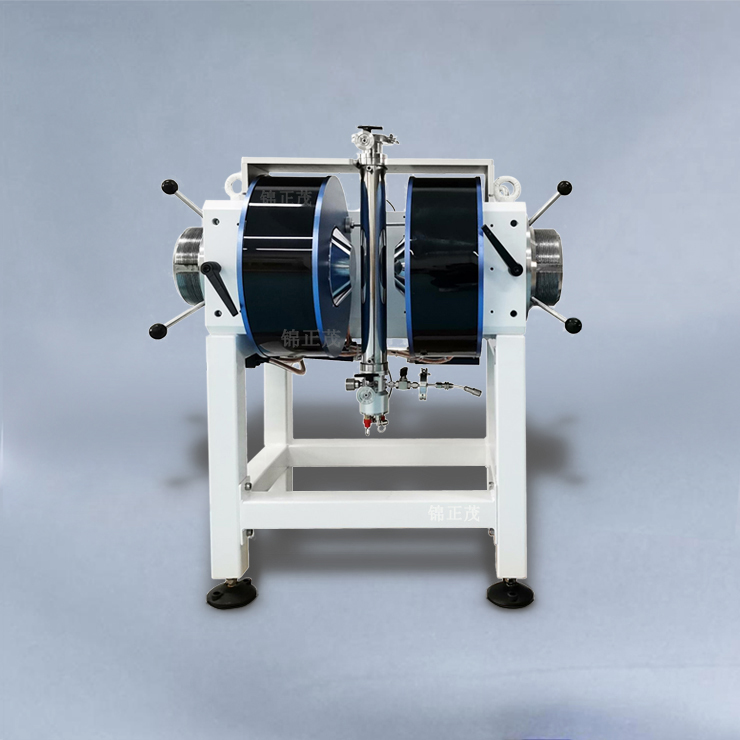

Vacuum Magnetic Field Annealing High Temperature Furnace

-

Vacuum Magnetic Field Annealing High Temperature Furnace

Jinzhengmao high temperature magnetic field annealing furnace is a set of feedback adjustment heating system composed of heating high temperature furnace, high temperature furnace heating power supply, Labview control software, electromagnet, high precision bipolar constant temperature power supply, molecular pump unit and water cooling unit.

Product Description:

The high-temperature vacuum magnetic field heating furnace system produced by Beijing Jinzhengmao Technology Co., Ltd. is composed of a heating high-temperature furnace, a high-temperature furnace heating power supply, Labview control software, an electromagnet, a high-precision bipolar constant temperature power supply, a molecular pump unit, and a water cooling unit. A set of feedback-regulated heating systems.

The high-temperature magnetic field heating furnace system is firstly pumped by the mechanical pump (dry pump) in the molecular pump group to the vacuum chamber (sample chamber), and when the ultimate vacuum that can turn on the molecular pump is reached, the molecular pump is turned on for high vacuum. Extraction to achieve the vacuum degree required by the customer. Open the software, enter the required magnetic field value and temperature value in the software, and adjust the temperature of the sample in the device automatically and stabilize at a certain temperature value through closed-loop feedback adjustment. The software can complete the experiment according to the experimental conditions given by the user.

Magnetic field control: The user can directly set the required magnetic field size through the software, read the actual magnetic field value by the high-precision gauss meter, and then feed the actual read-out magnetic field value to the high-precision constant current power supply. After processing by the internal software of the power supply, The output current of the high-precision constant current power supply is directly controlled, so as to realize the magnetic field required by the user and display it on the software in real time;

Temperature control: The required temperature value is directly set through the human-computer interaction interface on the software, and after the computer software is processed, the instruction reaches the high-temperature furnace heating controller. The controller reads the actual temperature value of the sample area through the temperature sensor (thermocouple), and adjusts the output current through the fuzzy control PID set inside it, so that the temperature value is stabilized within a certain accuracy range, so as to achieve the user's desired value. different temperatures required.

Vacuum environment: The vacuum environment is obtained by the molecular pump group, displayed and monitored by the high vacuum full-scale vacuum gauge, and the test results are transmitted to the computer in real time.

Annealing process: heat the sample in a strong magnetic field (or non-magnetic) environment, heat it to a certain temperature (the user needs to set it by himself) and keep it at this temperature, and then continue to add a magnetic field (which can be changed at any time) to achieve the purpose of the user After that, turn off the magnetic field, turn off the heating environment, and cool to room temperature.

Sample environment: The high temperature magnetic field heating furnace can place the tested sample in a strong magnetic field, high vacuum and high temperature environment at the same time. At the same time, these three experimental environments can also be combined individually or arbitrarily to meet the testing requirements of different samples in different environments.

Adaptation:Various soft magnetic materials that need to be heated or demagnetized in high temperature, high vacuum, and strong magnetic field environments.

Main Specifications:

※ The vacuum chamber and main parts are made of 304 non-magnetic stainless steel;

※ The vacuum acquisition system used is a molecular pump group; the vacuum measurement is a digital full-scale vacuum gauge;

※ Vacuum degree and leak rate:① Ultimate vacuum degree of vacuum chamber6´10-5Pa(cold state);②leak rate<10-11Pa.L/s,The degree of vacuum fluctuates with temperature, which is normal;

※ From room temperature to 900 degrees, the heating rate is better than 100K/min, and the high temperature heating temperature is 1000℃; temperature control accuracy: ±1℃;

※ During heating, the heating wire is encapsulated in a quartz tube, which greatly reduces the contamination of the sample surface adhesion caused by the volatilization of the heating wire;

※ Matching magnet power supply: bipolar, stability better than 50ppm/h, smooth zero-crossing without breakpoint;

※ Matching electromagnet: long-term running stability <±0.5Gs;

※ Cooling method: water cooling.